Interlocking Fly Ash Brick Machine

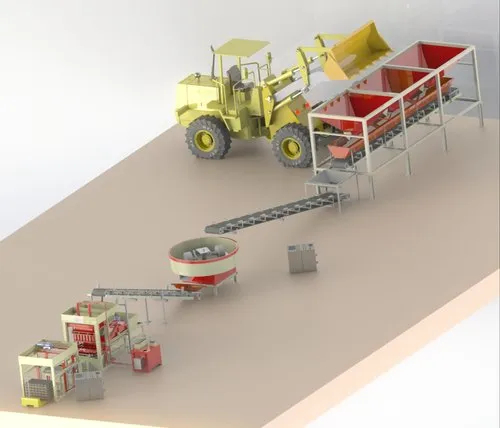

An Interlocking Fly Ash Brick Machine is a specialized machine designed to produce interlocking bricks using fly ash, sand, cement, and sometimes lime or gypsum. These bricks are designed with tongue-and-groove features that lock into each other, minimizing the need for mortar and enhancing wall strength and alignment.

These machines are widely used in low-cost housing, eco-friendly construction, and urban/rural development projects.

| Component | Material | Function |

|---|---|---|

| Steel Frame | Structural body | |

| Mould Set | Hardened steel (EN8 or EN31) | Brick shaping with interlock design |

| Hydraulic System | Cylinders, valves, power pack | Applies pressure to compress mix |

| Electric Control Panel | Relay or PLC-based | Operation automation |

| Feeder Hopper | MS Sheet with lining | |

| Pan or Concrete Mixer | Cast iron/mild steel | Mixes raw materials |

| Vibration Motor (Optional) | Heavy-duty electric motor | Improves density and strength |

Design: CAD/CAM design of brick size and interlocking pattern.

Frame Fabrication: MS frame is cut, welded, and aligned.

Machining: Mold cavities and hydraulic parts are precision-machined.

Hydraulic Assembly: Power pack, hoses, oil tank, and cylinders are installed.

Electrical Panel Setup: PLC or manual control panel installed and tested.

Painting and Finishing: Anti-rust coating, enamel paint, and branding applied.

Raw Material Preparation:

Sand/stone dust (2030%)

Cement (812%)

Water (optimal for binding)

Mixing: Ingredients are blended in a pan/concrete mixer.

Feeding: Material fed into the mold manually or automatically.

Moulding & Compression:

Hydraulic pressure (up to 120 bar) compresses material in the mold.

Interlocking shape is formed.

Ejection & Curing:

Bricks are ejected and stacked.

Water-cured for 728 days for strength.

Load-bearing and non-load-bearing walls

Temporary structures and housing schemes

Pavements and landscaping (with alternate molds)

Earthquake-resistant structures

Slum rehabilitation and low-cost housing projects

Replaces clay bricks and preserves topsoil

Enhances modular construction with faster assembly

Reduces construction cost and time

| Advantage | Description |

|---|---|

| Interlocking Fit | Bricks fit together perfectly; reduces mortar need |

| High Strength | Compression strength 812 MPa |

| Water Resistance | Minimal water absorption, reduces seepage |

| Fast Construction | Dry stacking method is quicker |

| Eco-Friendly | Uses fly ash; reduces pollution |

| Cost-Saving | |

| Reusable | Can be disassembled and reused in temporary structures |

Rural and Urban housing boards

Private developers and NGOs

Green building and sustainable housing

Industrial site boundary walls

Disaster-resilient structures

A: Interlocking bricks have a tongue-and-groove design that allows dry stacking and faster construction without mortar.

A: Yes. Curing for 7 to 28 days is essential for strength development.

A: Based on automation:

Manual: 8001000 bricks/day

Semi-auto: 30006000 bricks/day

Fully auto: 10,00020,000+ bricks/day

A: Common sizes include 300x150x100 mm or 230x110x75 mm, but sizes can be customized.

A: Yes. MSMEs can benefit from Mudra Loans, subsidy under PMEGP, or State Rural Development grants.

With increasing demand for affordable, green, and rapid housing solutions, interlocking fly ash bricks are revolutionizing how buildings are made. They enable:

Reduced project timelines

Lower carbon footprint

Minimal skilled labor requirement

Modular designs and flexible usage

Their role is critical in disaster zones, low-cost housing schemes, and environmentally sensitive projects.

The Interlocking Fly Ash Brick Machine is a game-changer in the construction industry. Combining eco-consciousness, cost efficiency, and speed of building, these machines cater to the rising need for modular, sustainable, and high-performance construction materials.

Whether you are a builder, contractor, government agency, or NGO, investing in this technology empowers your project with modern, eco-friendly infrastructure capabilities.

Office Address

C-1, 77/1, Kaka Estate, Ambicanagar Road, Nr. National Plastic, Odhav, Ahmedabad β 382415, Gujarat, India.

Factroy Address

24, Shreeji Estate Near Sankalp Estate, Bakrol Cir, Ahmedabad-382430, Gujarat, India

mixwellindia@gmail.com

hardicengineering@gmail.com

+91 99042 01922

+91 98984 74351

Also Send Mail

© Hardic Engineering . All Rights Reserved.