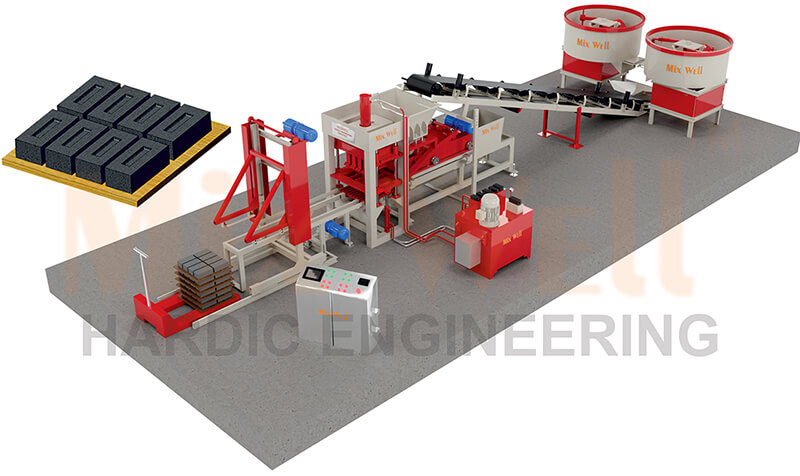

FAM-1440 Double Mixer

A double mixer is a dual-chamber mixing system used to prepare two types of material batches simultaneously—typically:

Base concrete mix (fly ash, cement, stone dust, etc.)

Color mix or topping (used for paver blocks or interlocking bricks)

In the FAM-1440 fly ash brick making plant, the double mixer boosts efficiency by preparing two distinct batches at once, thereby reducing downtime and increasing throughput.

How It’s Made – Components & Manufacturing

| Part | Material | Purpose |

|---|---|---|

| Mixer Pan x 2 | Mild Steel / MS + Hard Plate | Dual mixing chambers |

| Gearbox | Heavy-duty Cast Iron | Power transmission for mixing arms |

| Mixing Blades (Arms) | Hardened Alloy Steel | Blend materials evenly |

| Main Frame | ISMC/ISMB Section | Structural base |

| Drive Motor | 7.5–10 HP (x2) | Powers individual mixers |

| Discharge Door | Manually or pneumatically operated | Controlled output |

| Bearings & Shaft | EN8 / EN19 | High torque and load-bearing capacity |

Design Engineering – CAD design for two mixer pans with optimized blade rotation.

Fabrication – Laser-cut mild steel plates are bent and welded to form pans.

Machining – Shafts and gearbox components are precision-machined.

Assembly – Each pan gets its own gearbox, arms, and motor mounted.

Electricals – Motors wired individually or to a PLC for smart control.

Testing – Dry and wet testing done to ensure smooth, uniform mixing.

Raw Material Input

Different materials are loaded into the two pans—e.g., fly ash mix in one, color mix in the other.

Independent Operation

Each mixer works on its own motor and gearbox to mix the content uniformly.

Simultaneous Discharge

After mixing (usually 2–4 mins), materials are discharged into trolleys or feeders for molding.

Cycle Reset

Mixers are cleaned and reset for the next batch, running in a continuous loop.

| Specificatio n | Value |

|---|---|

| Number of Mixers | 2 (dual pan) |

| Capacity (each pan) | 300–500 kg |

| Motor Power | 7.5–10 HP per mixer |

| Mixing Time | 2–4 minutes |

| Blade Material | EN8/EN24 Hardened Steel |

| Discharge Type | Manual / Pneumatic |

| Gearbox Type | Helical / Planetary |

Dual Operation – Mix two different materials simultaneously (saves time).

Increased Output – Eliminates delay between material batches.

Better Resource Allocation – Operator can manage more machines at once.

Versatility – Ideal for bricks, pavers, color topping, interlocking tiles.

| Feature | Benefit |

|---|---|

| Parallel Mixing | Doubles the plant’s material readiness |

| Faster Cycles | Keeps pace with high-speed press machines |

| Material Quality | Uniform, lump-free mixing improves brick strength |

| Rugged Design | Designed for industrial 24/7 use |

| Flexible Use | Can be used for color mix, fly ash, concrete, etc. |

| Easy Cleaning | Two pans reduce contamination risk between materials |

Fly ash brick plants (semi & fully automatic lines)

Paver block manufacturing setups

Industrial tile and color topping production units

Government construction material plants

High-output manufacturing units with automated lines

A: Absolutely. A double mixer cuts down wait time by preparing two different batches at once—ideal for automated lines.

A: Yes. One mixer can handle fly ash while the other can be used for color mix or cement slurry.

A:

Daily: Clean pans and remove stuck mix

Weekly: Check gear oil and blade condition

Monthly: Lubricate bearings and inspect motor alignment

A: Yes. It can be integrated with relay or PLC panels for fully automatic operations.

A: With regular maintenance, a double mixer lasts 8–10 years in industrial use.

The FAM-1440 Double Mixer is a game-changing component for modern fly ash brick and block manufacturing units. Its dual mixing capability enhances productivity, versatility, and cost-efficiency by ensuring two types of mix are always ready without delay.

If you're running a semi or fully automatic line like the FAM-1440, upgrading to a double mixer is essential for scaling operations and optimizing production cycles.

Office Address

C-1, 77/1, Kaka Estate, Ambicanagar Road, Nr. National Plastic, Odhav, Ahmedabad – 382415, Gujarat, India.

Factroy Address

24, Shreeji Estate Near Sankalp Estate, Bakrol Cir, Ahmedabad-382430, Gujarat, India

mixwellindia@gmail.com

hardicengineering@gmail.com

+91 99042 01922

+91 98984 74351

Also Send Mail

© Hardic Engineering . All Rights Reserved.