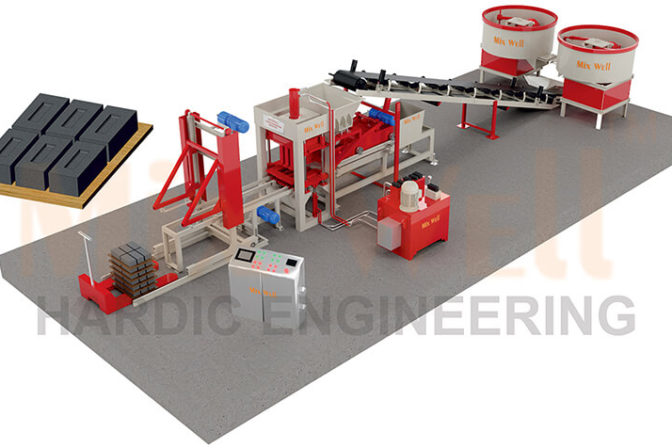

FAM-1080 Double Mixer

The FAM-1080 Double Mixer is a dual-chamber material mixing unit designed for use in semi-automatic and automatic fly ash brick and block production lines. It prepares two different material batches simultaneously, such as:

Fly ash, cement, and stone dust mix for bricks

Color mix or topping material for paver blocks

This setup boosts efficiency, output speed, and material quality while minimizing production delays.

| Component | Material | Purpose |

|---|---|---|

| Mixer Pans (2) | Dual mixing containers | |

| Mixing Arms/Blades | Hardened Steel | Blends raw materials evenly |

| Gearbox (x2) | CI Housing, Helical Type | Power transmission |

| Electric Motors | 5–7.5 HP each | Drives the mixers |

| Support Frame | ISMC/ISMB Channel | Base and structural support |

| Discharge Mechanism | Manual / Pneumatic Door | |

| Bearings & Shafting | EN8/EN19 | Withstands mixing torque |

| Electrical Controls | Relay or PLC | Automates cycle timing |

Design: CAD-based design suited for the FAM-1080 production line.

Fabrication: CNC and laser-cut mild steel plates are formed into dual mixer pans.

Machining: Gearboxes, shafts, and blade holders are precision-machined.

Assembly: Each mixer pan is equipped with its own gearbox, motor, and arms.

Electricals: Control wiring, motor connections, and automation interfaces.

Trial & Testing: Wet/dry mixing is tested under load for timing and quality.

Material Loading – Raw materials (fly ash, dust, sand, etc.) are fed into both mixer pans manually or via conveyor.

Dual Mixing – Motors rotate mixing arms inside both pans, blending materials in parallel.

Discharge – Once mixed, materials are discharged via gates into trolleys or pre feeders.

Cycle Repeat – Continuous loading/mixing/discharging ensures uninterrupted production.

| Specification | Value |

|---|---|

| Number of Mixers | 2 (dual pan system) |

| Capacity (each pan) | 250–350 kg |

| Motor Power | 5–7.5 HP x 2 |

| Blade Count | 4–6 per pan |

| Mixing Time | 2–4 minutes |

| Gearbox Type | Helical, planetary optional |

| Frame Material | ISMC 100+ channels |

| Control Type | Manual/Relay/PLC optional |

Parallel Mixing: Cuts idle time by preparing two batches at once.

Consistent Quality: Uniform mixing ensures strength and density in bricks/blocks.

Time Efficient: No need to wait between batches—ensures faster production cycles.

Versatile Mixing: Supports color mix, fly ash mix, concrete topping mix, etc.

| Advantage | Description |

|---|---|

| Efficient Design | Dual motors & pans double productivity |

| Robust Structure | Industrial-grade steel for long-term usage |

| Easy Maintenance | Simple disassembly and blade access |

| Improved Output | Supports high-speed press machines |

| Scalable | Works well with small and mid-size plants |

| Reduced Downtime | Always one pan ready to discharge while the other mixes |

FAM-1080 fly ash brick machine production lines

Mid-sized construction material factories

Municipal and contractor-based production units

SME manufacturing setups

A: A double mixer prepares two batches in parallel, reducing downtime and increasing plant output. It's ideal for color mix + base mix requirements.

A: Yes. Though optimized for FAM-1080 systems, it can be modified to suit similar-capacity press machines or tile lines.

A:

Daily: Clean pans after every shift

Weekly: Check blade sharpness and oil levels

A: Yes. The FAM-1080 double mixer can be operated via relay logic or fully integrated into a PLC control panel for automated cycle timing and discharge.

A: Yes. One mixer can be dedicated for color/topping mix while the other prepares the base mix.

The FAM-1080 Double Mixer is a strategic upgrade for mid-sized fly ash brick and block plants. By preparing multiple material types at once, it ensures continuous operation without waiting for a single mix to complete. This improves operational efficiency, batch consistency, and plant productivity.

The FAM-1080 Double Mixer is a reliable, high-performance unit that forms the backbone of efficient, semi-automatic brick and block production. Its robust design, flexible application, and dual-batch capability make it a smart investment for manufacturers seeking to maximize output and maintain superior material quality.

If you are installing or upgrading to a FAM-1080 line, the double mixer is an essential component that will future-proof your operations.

Office Address

C-1, 77/1, Kaka Estate, Ambicanagar Road, Nr. National Plastic, Odhav, Ahmedabad – 382415, Gujarat, India.

Factroy Address

24, Shreeji Estate Near Sankalp Estate, Bakrol Cir, Ahmedabad-382430, Gujarat, India

mixwellindia@gmail.com

hardicengineering@gmail.com

+91 99042 01922

+91 98984 74351

Also Send Mail

© Hardic Engineering . All Rights Reserved.