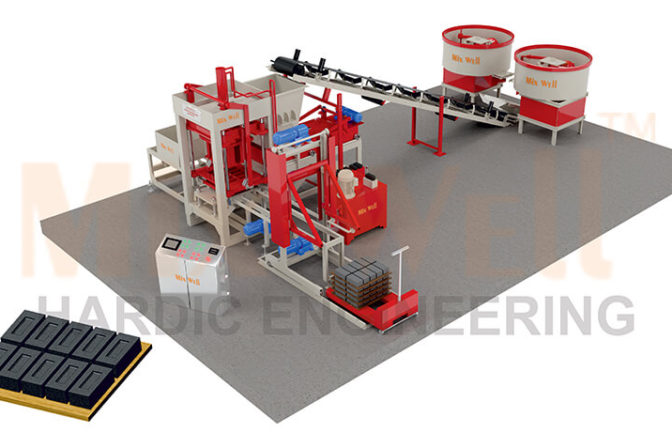

FAM-1800 With Batching Plant

The FAM-1800 with Batching Plant is a semi-automatic or fully automatic fly ash brick manufacturing system equipped with a batching plant that ensures precise, automatic weighing and proportioning of raw materials like fly ash, cement, stone dust, and water.

This integrated setup offers high production capacity, reduced material wastage, and improved consistency in the quality of bricks or blocks.

| Component | Function |

|---|---|

| FAM-1800 Press Machine | Hydraulic/vibro press for brick molding |

| Batching Plant Unit | Auto batching of raw materials |

| Double Pan Mixers | Mixes materials into a uniform consistency |

| Conveyor Belts | Transfers materials to mixers and press |

| Hydraulic Power Pack | Powers the press system |

| Control Panel (PLC/Manual) | Synchronizes batching, mixing, and pressing |

| Feeder & Hopper System | Transfers batch mix to pressing unit |

| Storage Bins | Store fly ash, cement, aggregates |

| Water Dosing Unit | Precise water addition to the mix |

Design Engineering

Steel Fabrication

Heavy-duty frames for the press and batching structure.

Mechanical Assembly

Hydraulic System Integration

High-pressure pumps, valves, and tanks mounted.

Automation Wiring

Sensors, motors, PLC programming for automated operations.

Calibration & Testing

Material Loading

Fly ash, sand, cement loaded into dedicated bins.

Automatic Batching

Weighed in programmed ratios using load cells.

Mixing

Conveyor Transfer

Mixed material transferred to pre-feeder.

Brick Pressing

Hydraulic or vibro-press compresses material into bricks.

Curing

| Parameter | Value |

|---|---|

| Production Capacity | 18,000 22,000 bricks/day |

| Power Requirement | |

| Operation | Semi or Fully Automatic |

| Hydraulic Pressure | Up to 150 bar |

| Brick Types | Fly Ash, Paver, Hollow |

| Water Dosing | Auto with timer |

| Cycle Time | 1215 seconds |

| Raw Material Storage | 34 bins, 12 tons each |

| Industry | Application |

|---|---|

| Housing Projects | Brick supply for walls and partitions |

| Brick Plants | |

| Infrastructure | Roads, footpaths, culverts |

| Factories | Boundaries, sheds, interiors |

| Smart Cities | Sustainable brick solutions |

Automatic batching ensures exact weight-based material proportioning key for high-strength bricks.

Reduces manual labor, avoids errors in mix quality, and saves time.

Maintains homogeneous mixture consistency, leading to crack-free, strong bricks.

Reduces cement overuse, material wastage, and human error resulting in cost savings.

| Advantage | Description |

|---|---|

| Smart Batching | |

| Continuous Mixing | No production halt due to dual mixer system |

| Better Brick Quality | Uniform strength, size, and finish |

| Operational Savings | Less manual labor needed |

| Time Efficient | Reduces cycle time and increases daily output |

| Modular Setup | Easy integration and scalability |

| Low Maintenance | Robust mechanical design and fewer moving parts |

Government Housing Projects (PMAY, NREGA)

Private Brick Manufacturing Plants

Export-Oriented Brick Units

Construction Equipment Parks

A: Manual batching often results in inconsistent brick quality due to improper raw material ratios. Automatic batching ensures precision and repeatability.

A: Typically, 1015 working days for full installation, calibration, and commissioning.

A: Not mandatory, but PLC control improves efficiency by automating batching, timing, and mixing.

A: Yes, with interchangeable moulds, you can produce fly ash bricks, paver blocks, hollow blocks, and more.

A: Minimal. Basic training enables workers to operate the panel and conduct routine maintenance.

A: Depending on your market, ROI is typically 612 months with regular production.

The FAM-1800 with Batching Plant is a powerful, precise, and scalable fly ash brick production solution that brings automation and consistency to your manufacturing process. With accurate batching, dual mixing, and robust pressing, it ensures top-tier brick quality, higher daily output, and cost efficiency for growing and professional brick plants.

Office Address

C-1, 77/1, Kaka Estate, Ambicanagar Road, Nr. National Plastic, Odhav, Ahmedabad β 382415, Gujarat, India.

Factroy Address

24, Shreeji Estate Near Sankalp Estate, Bakrol Cir, Ahmedabad-382430, Gujarat, India

mixwellindia@gmail.com

hardicengineering@gmail.com

+91 99042 01922

+91 98984 74351

Also Send Mail

© Hardic Engineering . All Rights Reserved.