F-2160 Double Machine

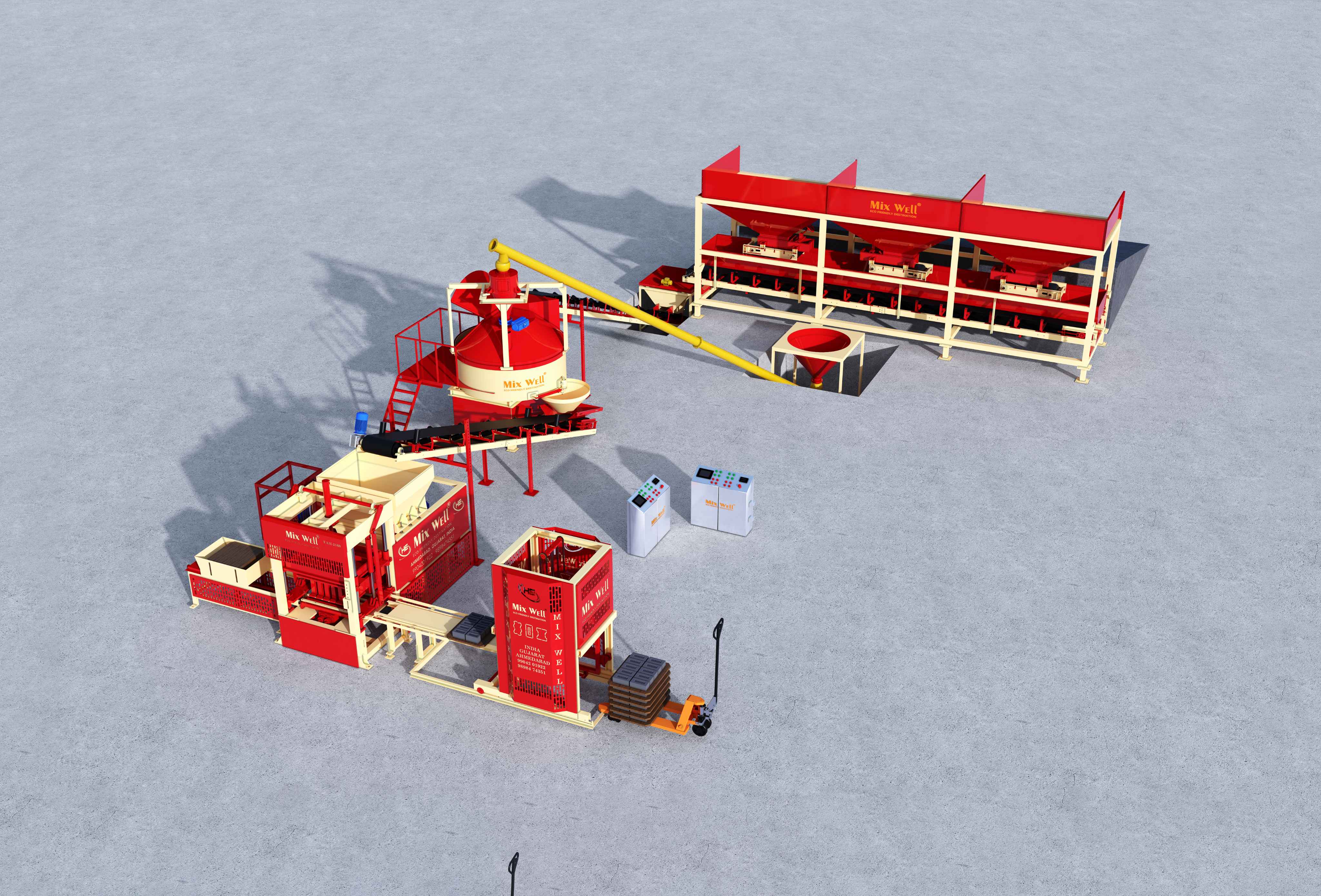

The F-2160 Double Machine refers to a dual-mould or twin production unit version of the standard F-2160 fly ash brick machine. It is engineered for maximum productivity, producing double the number of bricks per cycle compared to single-machine units by operating two hydraulic moulding stations simultaneously.

It is used for large-scale brick manufacturing plants that need high output, continuous operation, and product consistency.

| Component | Function |

|---|---|

| Twin Hydraulic Press Units | Two independent or synchronized pressing stations for high-speed production |

| Heavy-Duty Frame | Reinforced steel structure for dual operation stability |

| Twin Feeding Conveyor | Transfers raw mix to both moulds |

| Central PLC Control System | Operates and synchronizes both machines |

| Hydraulic Power Unit (Double Capacity) | Powers dual mould cylinders |

| Interchangeable Moulds | Produces bricks, blocks, pavers of different sizes |

| Vibrators + Hydraulic Press | Ensures compact bricks with precise shape |

| Material Batching Plant (Optional) | Weighs and mixes raw materials automatically |

| Curing Section | Manual or automated curing area for finished bricks |

Design Engineering

Frame Fabrication

Mild steel plates, channels, and joints are cut, welded, and assembled for heavy-duty support.

CNC Machining

Accuracy-machined components like moulds, guides, and cylinder mounts.

Hydraulic System Integration

Automation & Control Wiring

PLC and HMI system installed to control both units centrally.

Quality Check & Testing

Dry and live tests to ensure output consistency, hydraulic balance, and mould alignment.

Raw Material Preparation

Material Feeding

Mixed material delivered to both moulds via twin conveyors or feeders.

Dual Pressing

Two hydraulic systems compress the material simultaneously into bricks.

Brick Ejection

Finished bricks are automatically or semi-automatically ejected to pallets.

Curing

Natural or steam curing ensures strength development.

| Feature | Specification |

|---|---|

| Output Capacity | 43,200 bricks per 8-hour shift (approx.) |

| Hydraulic Pressure | 120160 bar |

| Power Requirement | 6075 HP |

| Brick Size | |

| Cycle Time | 1215 seconds (both stations) |

| Automation | Fully automatic with PLC and HMI |

| Mixer Capacity | 10001500 kg per batch |

| Area Requirement | 30,00040,000 sq. ft. |

| Industry | Application |

|---|---|

| Real Estate | Construction of villas, apartments, commercial buildings |

| Infrastructure | |

| Government Housing | PMAY, rural housing missions |

| Brick Manufacturing Units | Mass-scale fly ash brick production |

| Industrial Zones | Boundary walls, flooring, storage sheds |

Capable of producing over 40,000+ bricks per day, ideal for export or large tenders.

Bricks maintain consistent compressive strength, finish, and size due to synchronous pressing.

Reduced labor cost per brick due to automation and higher throughput.

Better ROI on land, electricity, and material due to dual operation.

Supports integration with batching plants, solar systems, and remote monitoring.

| Advantage | Description |

|---|---|

| Dual Output | Two moulds working in parallel doubles productivity |

| Uniform Bricks | |

| Eco-Friendly | Uses fly ash and reduces dependence on fired clay bricks |

| Automated System | Reduced human error, better consistency |

| Flexible Operation | Run single or both units as per requirement |

| High ROI | Payback within 1218 months for high-capacity manufacturers |

| Customizable | Moulds can be changed for bricks, pavers, blocks |

Fly Ash Brick Plants

Export-Oriented Manufacturing Units

Mega Infrastructure Projects

Urban Smart Cities Development

Industrial Construction Sites

Government Tender Contractors

A: It doubles output without doubling workforce or land area, increasing efficiency and profits.

A: Not significantly. Proper maintenance of hydraulic and electrical systems keeps both machines running efficiently.

A: In advanced models, independent control allows maintenance on one unit while the other runs.

A: Around 30,00040,000 sq. ft. including curing, storage, and operational space.

A: With proper maintenance, the machine has a service life of 15+ years.

A: Yes, it can work with DG sets, solar inverters, and battery-backed systems.

The F-2160 Double Machine is a next-generation high-performance fly ash brick making solution built for industrial-scale production. Its dual system maximizes productivity while maintaining exceptional product quality. Perfect for modern construction projects, government schemes, and high-volume exports, it offers one of the highest ROI in the construction machinery industry.

If you're aiming for bulk production with minimum error and maximum speed, the F-2160 Double Machine with or without batching integration is your ideal choice.

Office Address

C-1, 77/1, Kaka Estate, Ambicanagar Road, Nr. National Plastic, Odhav, Ahmedabad β 382415, Gujarat, India.

Factroy Address

24, Shreeji Estate Near Sankalp Estate, Bakrol Cir, Ahmedabad-382430, Gujarat, India

mixwellindia@gmail.com

hardicengineering@gmail.com

+91 99042 01922

+91 98984 74351

Also Send Mail

© Hardic Engineering . All Rights Reserved.